Unlock the Secrets of the Best 3D Printer Filaments You'll Wish You Knew Sooner!

When it comes to 3D printing, the filament you choose can make all the difference between a successful project and a frustrating failure. The right filament not only influences the quality and durability of your prints but also affects the ease of use and print speed. With a plethora of options available, ranging from biodegradable materials to robust thermoplastics, selecting the best 3D printer filament can be overwhelming. Understanding the characteristics of each type of filament will help you make informed decisions, ensuring that your creations turn out exactly as envisioned. Whether you're a hobbyist looking to make intricate models or an engineer prototyping a new product, the filament you choose plays a crucial role in your 3D printing journey.

Understanding 3D Printer Filaments

3D printer filaments are the raw materials used in fused deposition modeling (FDM) printers to create three-dimensional objects. These filaments are typically made from thermoplastics, which means they can be melted and reshaped multiple times without degrading. The properties of the filament, such as its melting point, viscosity, and adhesion qualities, directly affect the final print quality. For instance, a filament with a low melting point may print faster but could result in weaker structures, while a high-temperature filament may produce strong, durable prints but require more precise temperature control. A good friend of mine, who recently started 3D printing, discovered this firsthand when he attempted to print a model with a low-quality filament, only to find it warping during the process. Understanding these properties is essential for achieving optimal results in your 3D printing endeavors.

Types of 3D Printer Filaments

There are several types of 3D printer filaments available, each with its own unique properties and applications. One of the most popular is PLA (Polylactic Acid), known for its ease of use and environmentally friendly composition. PLA is biodegradable and produces minimal odor during printing, making it a favorite among beginners. However, it is less heat-resistant compared to other filaments, which may limit its use in high-temperature applications.

ABS (Acrylonitrile Butadiene Styrene) is another widely used filament, prized for its strength and durability. It is ideal for functional parts and can withstand higher temperatures than PLA. However, ABS does emit fumes when heated, necessitating proper ventilation.

PETG (Polyethylene Terephthalate Glycol) combines the best properties of PLA and ABS, offering strength, flexibility, and chemical resistance. It is easy to print and produces durable parts, making it a great choice for a variety of applications.

Lastly, TPU (Thermoplastic Polyurethane) is a flexible filament that can be used for creating soft and stretchy parts, such as phone cases or wearable items. While it offers unique advantages, printing with TPU can be tricky due to its flexibility, which may lead to feeding issues in some printers.

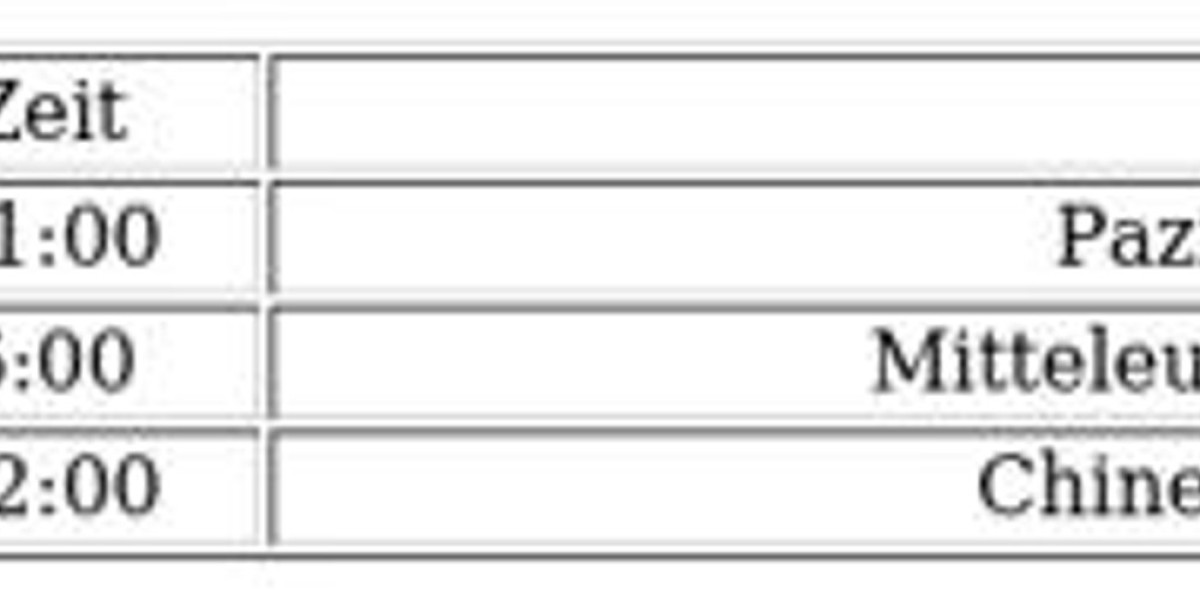

Comparative Analysis of Popular Filament Types

When comparing different filament types, several factors come into play. Strength is a significant consideration—ABS generally outperforms PLA in this area, making it suitable for functional prototypes. However, PLA's rigidity can be advantageous for decorative items that don't require heavy-duty use.

Flexibility is another key aspect. TPU reigns supreme here, allowing for the creation of parts that need to bend or stretch, while PLA and ABS are both rigid once printed.

Ease of use is vital for beginners; PLA is often recommended due to its forgiving nature and lower printing temperature. On the other hand, ABS requires a heated bed and careful environmental control to prevent warping.

Temperature resistance also varies significantly among these filaments. While PLA can start to deform at around 60°C, ABS and PETG can handle higher temperatures, making them better suited for applications exposed to heat.

Factors to Consider When Choosing Filament

When selecting the right filament for your project, several key factors should be considered. First and foremost is printer compatibility; not all printers can handle every type of filament. Checking the manufacturer's specifications regarding filament diameter and type ensures successful printing.

Filament diameter is another important aspect, with the most common sizes being 1.75mm and 2.85mm. Your printer's nozzle size and feed mechanism will dictate which diameter is appropriate.

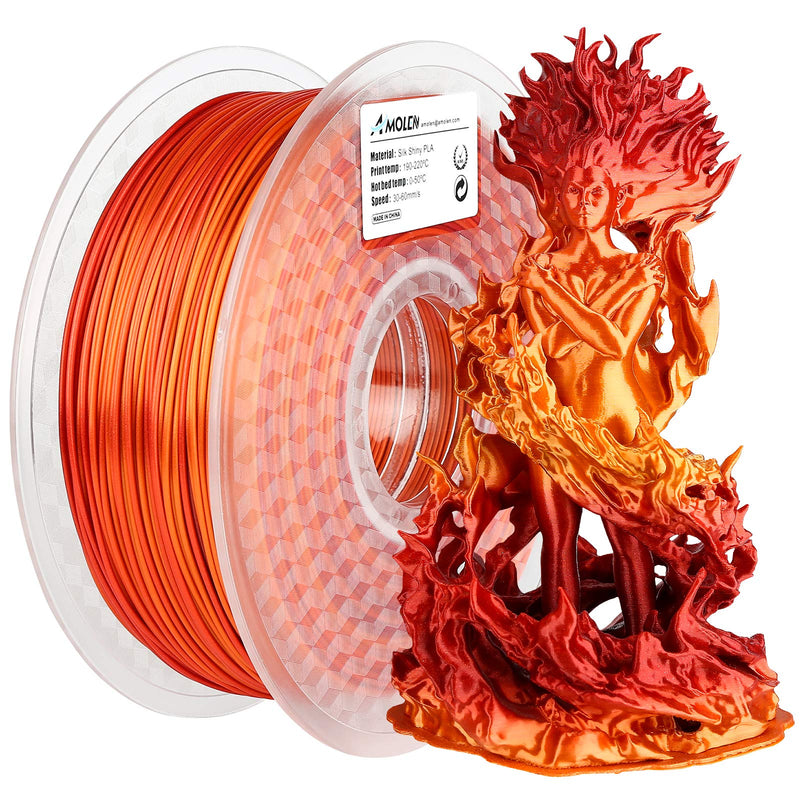

Color options can significantly impact your design's aesthetics. Many filaments come in a wide range of colors, and some even offer specialty finishes like metallic or glow-in-the-dark, which can enhance the final product's appeal.

Lastly, consider the environmental impact of the filament you choose. Biodegradable options like PLA are more eco-friendly, while traditional plastics can take hundreds of years to decompose. Making an environmentally conscious choice can contribute to more sustainable 3D printing practices.

Choosing the Right Filament for Your 3D Printing Needs

In summary, selecting the best 3D printer filament is crucial for achieving high-quality prints and enhancing your overall printing experience. By understanding the various types of filaments available and their unique properties, you can make informed decisions that align with your specific needs and projects. Whether you prioritize strength, flexibility, ease of use, or environmental considerations, knowing your options will empower you to create stunning 3D prints with confidence. So, dive into the world of 3D printing, and let your creativity flourish with the right filament by your side!