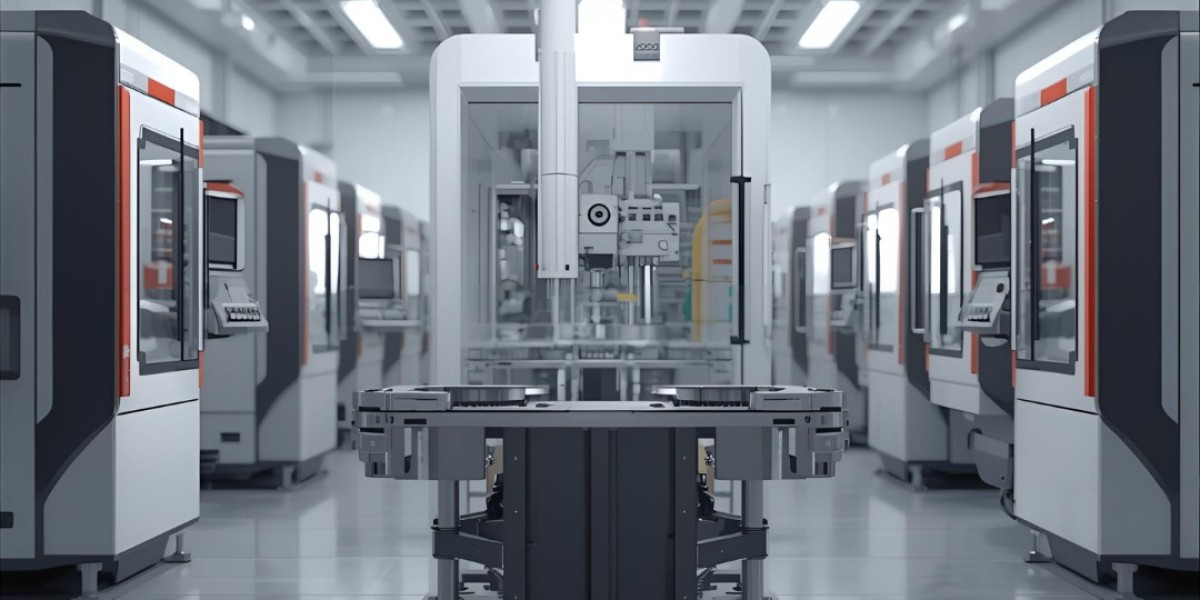

The industrial landscape of the UAE is rapidly evolving, driven by innovation, automation, and advanced engineering practices. From oil and gas to construction and aerospace, industries depend heavily on precision-engineered components that meet the highest standards of accuracy and durability. This is where precision custom machining manufacturers play a pivotal role, offering tailored solutions that ensure optimal functionality across applications. These manufacturers collaborate closely with industrial equipment suppliers in UAE to deliver components that are not only reliable but also engineered to perform under demanding conditions. Together, they form the foundation of the region’s growing manufacturing ecosystem—one built on quality, precision, and long-term performance.

Understanding the Role of Precision Custom Machining Manufacturers

Precision custom machining manufacturers specialize in producing intricate, high-tolerance components using advanced CNC technologies. These parts are used in industries where precision is not optional but essential—such as oil and gas exploration, industrial automation, and heavy machinery. Through computer-controlled machining processes, these manufacturers achieve levels of accuracy that traditional machining methods cannot match. Every component is designed and fabricated according to exact client specifications, ensuring flawless integration with existing systems. The importance of precision machining lies in its consistency. Whether producing a single prototype or a full-scale production run, manufacturers guarantee identical results every time. This precision not only enhances product performance but also extends the lifespan of equipment, reducing maintenance costs and downtime.

Partnership Between Machining Manufacturers and Equipment Suppliers

Collaboration between precision custom machining manufacturers and industrial equipment suppliers in the UAE is vital to the country’s industrial success. Suppliers provide the link between manufacturers and end-users, ensuring that the right components reach the right industries efficiently. By working together, these partners create a seamless supply chain that supports high-performance operations across multiple sectors. Equipment suppliers benefit from having access to customized, high-quality components, while machining manufacturers gain insight into market demands and evolving industry standards. This partnership enhances the UAE’s reputation as a hub for advanced engineering and manufacturing excellence. It ensures that clients receive end-to-end solutions—from custom part production to equipment integration and support.

The Importance of Precision in Modern Industries

In today’s competitive marketplace, precision determines performance. Industries such as aerospace, oil and gas, and energy production rely on components that can withstand high pressure, heat, and corrosive environments. Even a minor deviation in measurement can lead to costly equipment failures or safety risks. That’s why precision custom machining manufacturers use cutting-edge technologies like 5-axis CNC machining, CAD/CAM design systems, and automated quality inspections. These tools allow for the creation of highly accurate parts with tolerances measured in microns. For industrial equipment suppliers in the UAE, sourcing from precision manufacturers ensures that every component they deliver contributes to the overall efficiency and reliability of their client’s operations. This precision-driven approach helps businesses maintain consistent output, reduce rework, and extend the operational lifespan of critical assets.

Benefits of Working with Precision Custom Machining Manufacturers

Collaborating with precision custom machining manufacturers offers multiple advantages for industries across the UAE. The foremost benefit is customization—manufacturers can design parts tailored specifically to meet the functional and environmental needs of each project. This flexibility ensures better performance and reliability in critical applications. Additionally, these manufacturers emphasize material selection, ensuring that every part is engineered from the most suitable metals or alloys for its intended use. Another advantage is quality assurance. Every stage of the machining process undergoes rigorous testing and inspection, guaranteeing parts that meet international standards. For industrial equipment suppliers in the UAE, this level of assurance translates into improved credibility and customer satisfaction. The collaboration also promotes faster delivery times and localized support, both of which are vital for industries operating on tight project schedules. In short, precision manufacturing delivers the perfect blend of speed, accuracy, and reliability.

The Future of Precision Manufacturing in the UAE

The UAE continues to establish itself as a regional leader in advanced manufacturing, with government initiatives supporting technological innovation and industrial diversification. As part of this growth, precision custom machining manufacturers are adopting automation, robotics, and smart manufacturing systems to enhance productivity. This evolution benefits industrial equipment suppliers in the UAE, who can now access more sophisticated and sustainable components than ever before. With the integration of Industry 4.0 technologies, manufacturers can produce smarter, more efficient parts that align with modern energy and performance standards. In the coming years, the collaboration between machining manufacturers and equipment suppliers will become even more critical. Together, they will drive the UAE’s industrial transformation by providing innovative, cost-effective, and sustainable solutions for global markets.

Conclusion

Precision custom machining manufacturers form the backbone of industrial innovation in the UAE. Their expertise in producing high-quality, customized components enables industries to operate with greater precision, reliability, and efficiency. By working hand-in-hand with industrial equipment suppliers uae, these manufacturers ensure that local and global clients have access to the best engineering solutions available. This partnership represents a powerful combination of technological advancement and practical industry knowledge—one that continues to strengthen the UAE’s position as a leader in modern manufacturing. As industries demand ever-higher standards of accuracy and performance, precision machining will remain an essential driver of progress and excellence across the region.

FAQs

Q1: What do precision custom machining manufacturers do?

They design and produce high-accuracy, custom-engineered components used in industries such as oil and gas, construction, and aerospace.

Q2: Why is precision important in industrial manufacturing?

Precision ensures consistent performance, reduces equipment failures, and enhances overall operational efficiency.

Q3: How do industrial equipment suppliers in the UAE benefit from precision machining?

They gain access to reliable, high-quality components that improve their product offerings and customer satisfaction.

Q4: What technologies do precision machining manufacturers use?

They use CNC machines, CAD/CAM software, and automated inspection systems to achieve precise results.

Q5: How is the UAE advancing in precision manufacturing?

The UAE is investing in automation, robotics, and sustainable manufacturing technologies to enhance its industrial capabilities.