In industrial manufacturing, where purity, consistency, and efficiency determine product quality, quality control methods must be foolproof and safe. In the many systems and equipment being used in producing superior-quality products, magnetic grills have become a silent but critical solution to contamination due to ferrous contamination. No matter whether it is food processing, ceramics, chemicals, or plastics, having a magnetic grill incorporated in your manufacturing process can be life-changing.

This article talks about why businesses in most sectors would benefit from having magnetic grills as part of the quality control process, how they function, and what to choose from to meet a specific operational requirement.

The Importance of Contaminant-Free Processing

Metal contamination happens more often in industrial processes than one would imagine. It can be due to machinery wear and tear, impurities in raw materials, or even operator error. Ferrous particles ranging from visible screws to microscopic metallic dust have the potential to irreparably damage equipment, halt production, and most importantly, create sub-standard products or recalls.

Magnetic separation has been utilised far and wide in recycling facilities, mining facilities, and production lines to recover unwanted metal impurities from raw or processed products. When utilised in these applications, a magnetic grill plays the role of the first line of defence, capturing iron impurities before they become problematic downstream.

How Magnetic Grills Work

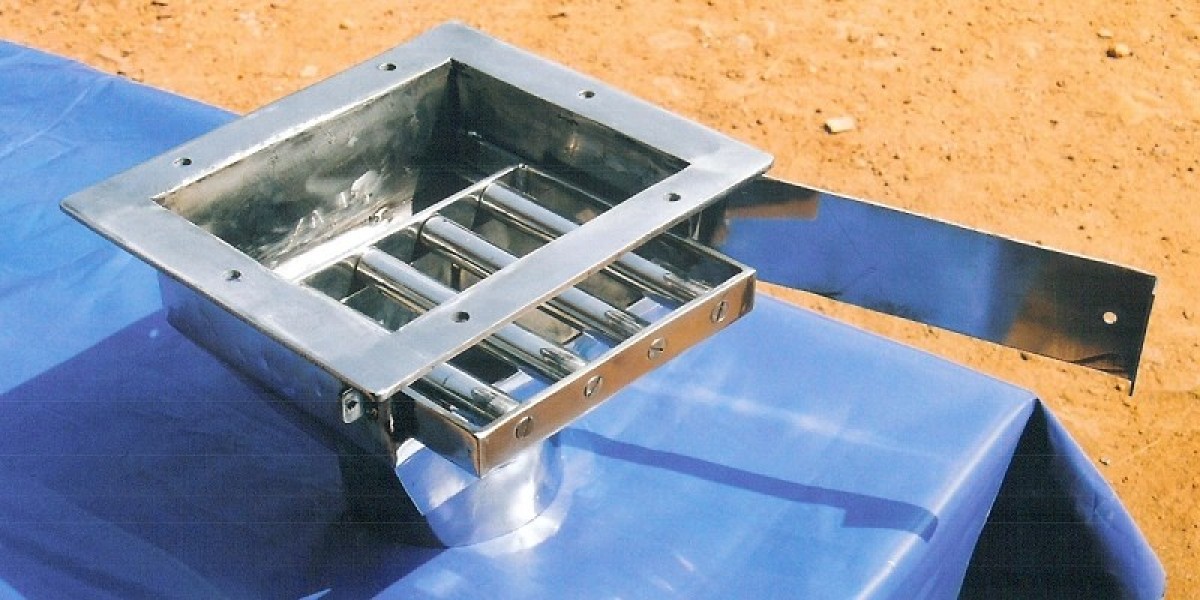

Magnetic grill is a highly efficient but simple unit made up of a collection of magnetic rods held in a grid-like casing. Positioned in hoppers, chutes, or pipelines, the grills are best located in the direction of flow for trapping ferrous particles.

When material travels over or through the grill, iron particles are attracted to and adhere to magnetic rods. They can be constructed for different flow rates, materials, and industry cleanliness levels, depending on the type of grill—round, rectangular, or drawer type.

As they are passive and utilise no electricity, magnetic grills are simple to clean and very reliable, a good choice for continuous operation.

Applications Across Industries

Magnetic grills' elasticity makes them applicable across a broad spectrum of industries:

Food & Beverage: Prevents metallic contamination in powdered and granular foods.

Pharmaceuticals: Sustains product purity necessary to keep regulatory safety measures in line.

Chemicals & Plastics: Protects processing equipment from iron chip corrosion.

Recycling & Mining: Preserves ferrous material for recycling or disposal.

These are the conditions in which any metallic impurity, no matter how small its magnitude may be, can influence the final product or improve the production cycle. Even Indian vibrating table manufacturers have their part to play in this context with a smooth and consistent supply of material to even more improve the efficiency of the magnetic grill in separation.

Pain Points Magnetic Grills Address

The following production line issues are usually experienced by companies:

Ununiform product quality because of contamination

Continuous breakdown of machinery by metal particles

Administrative non-compliance in the form of lower product quality

Lost customer faith and brand image

A magnetic grill eradicates all of these problems with one easy solution—efficient ferrous separation. Along with other quality control equipment like vibrating tables, the production process becomes much more efficient and devoid of contamination.

How Electro Flux Equipments Provides the Right Solution

Where magnetic separation quality solutions are the concern, Electro Flux Equipments Pvt Ltd is the solution to rely on due to its innovative design, durability, and service to customers. With years of experience and vast engagement in food processing to steel, to cement industries, they have an overwhelming variety of magnetic grills with general and specific applications.

What sets Electro Flux apart is that they are able to adapt products for the acceptance of various machinery configurations and special industry conditions. This flexibility is particularly important for companies that prefer to insert magnetic grills into complex production flows. Electro Flux products are built to be long-lasting with little maintenance, departing not from their "fit and forget" policy of engineering.

Also, Electro Flux understands that quality control is not the installation but a long-term commitment. Its repair shop (even for non-Electro Flux products), after-sales service, and single one-year service warranty give customers confidence that few can rival. Either a custom-designed magnetic separator or the incorporation of vibrating systems from industry leaders in vibrating table manufacturers in India, Electro Flux offers uninterrupted operation compatibility and performance.

Magnetic Grills and Vibrating Tables: The Perfect Pair

Worthy of note is the added benefit when vibrating tables are used with magnetic grills. While magnetic grills capture ferrous impurities, vibrating tables offer free-flowing material that reduces clumping and allows the magnetic grill to capture the impurities more effectively.

Leading vibrating table manufacturers in India have realised this cooperation and now design the systems upon magnetic grills, so integrating is easy and efficient. Between the two instruments, quality control becomes highly precise and trustworthy.

Conclusion: Invest in Purity, Reliability, and Efficiency

In the cutthroat marketplace of today, businesses cannot afford to stint on quality control. Magnetic grills offer a trouble-free, low-cost solution to a very practical dilemma—metal contamination. No matter what your application is, to protect equipment, ensure product purity, or comply with government regulations, this deceptively innocuous device has a deep impact.

If you're looking for a trusted partner to help you implement the right magnetic separation solution into your business, Electro Flux Equipments offers the intersection of engineering know-how, customisation, and after-sales service. Explore their range of magnetic grills and other industrial products and see how they can optimise your quality control strategy and future-proof your operations.